- The 2010 Haiti Earthquake, Part 1

- The 2010 Haiti Earthquake, Part 2

- Miyamoto in Haiti: The Presidential Palace, A Fractured Haitian Icon

- Miyamoto in Haiti: Damage Assessment of the Japanese Embassy

- Miyamoto in Haiti: The Well-Oiled Relief Machine Rolling Through Haiti

- Miyamoto in Haiti: Inside a Heavily Damaged Building

- Miyamoto in Haiti: Visiting The Citadel

- Thirty Months in Haiti, Part 1

- Thirty Months in Haiti, Part 2

- Thirty Months in Haiti, Part 3

- Miyamoto in Haiti: A Morning and Afternoon of Hopeful Rebuilding

- Miyamoto in Haiti: School Rebuilding and Construction Continues

- Trente mois en Haïti, 1eme partie

- Trente mois en Haïti, 2eme partie

- Trente mois en Haïti, 3eme partie

- Miyamoto in Haiti: Visiting a Remote School Construction Site Near Cap-Haïtien

- Miyamoto in Haiti: Self-Sustaining Relief

- Miyamoto in Haiti: Love it or Hate it? Love it!

- Miyamoto in Haiti: Lycee de Cite Soleil Rehabilitation Project

- Miyamoto in Haiti: The Hopeful Road to Recovery

- A Day in the Haiti Disaster Zone

- Kidnappers & Disaster

- A Disaster Week in Haiti

The team of engineers assessed each house and marked it with a green, yellow or red tag. Teams also recorded detailed structural and social information using PDAs. We not only performed engineering tasks, but we also became counselors and social workers. People were beginning to return home to safe, green-tagged houses. The temporary camp population had decreased to 700,000 in late 2010. We figured that the amount of debris that existed in the country, based on the database that we had developed, was 8.9 million cubic meters (314 million cubic feet). Based on this estimate, the United Nations Development Programme (UNDP) and USAID came up with a plan to take care of this debris.

We identified over 120,000 yellow-tagged houses with limited damage. They were still dangerous but relatively easy to repair. The now famous Yellow House Repair Program originated here. During this program’s initial assessment we identified more than 80,000 collapsed or heavily damaged buildings. These were red-tagged, a warning not to enter. A number of in-country NGOs started working to remove these buildings. This program won a Project of the Year award from UNOPS and the World Bank. This was not a job for everyone. We were often spread out in unstable and dangerous communities, but sometimes even notorious gang members helped to guide the engineers. Often, a disaster brings out the best in people. Haiti was no exception.

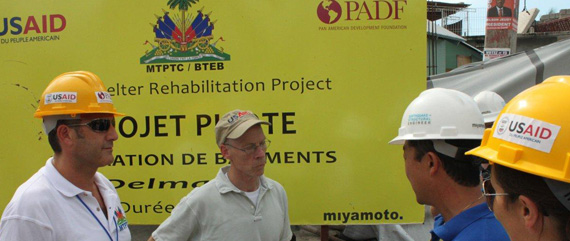

The next step was reconstruction. In early 2011, we were still struggling to cope with over 700,000 homeless, and a staggering amount of debris and half-collapsed buildings. No one knew where to start. We finally came up with the idea of “picking low-hanging fruit” as a reconstruction strategy. The target was 120,000 yellow-tagged houses. They were damaged, but repairable. Funded by the PADF and USAID OFDA, we formulated a repair program, much like we had done for the damage assessment program. Our experience of working in impoverished Haitian communities for the past 12 months was key. By this time, I had started to understand what made people tick. I became, by necessity, an amateur cultural anthropologist of sorts.

First we developed an MTPTC-approved guideline for seismic damage repair per international standards. Based on that guideline, we trained a team of master masons and engineering managers. We even flew in an American master mason from San Diego to train the first batch of mason trainers. Train the trainers—that was the best way to build a solid foundation. Over 6,000 masons and 600 engineers were eventually trained that way.

Next, we selected small commercial contractors to work on this program. This was unusual in Haiti. Usually, NGOs hired masons and laborers directly, or brought in international volunteers, skipping the commercial sector. Then, guest what? Good-intentioned, well-funded, non-profit organizations were directly competing against local businesses. That is how Haiti lost many of its industries, including its agricultural businesses. It was not easy to compete against “free rice.” This standard practice unintentionally had created a society that could not sustain itself without continual foreign aid. The commercial sector was destroyed and jobs were hard to find. Unemployment was over 80 percent. We wanted to do something different: invest in and train small Haitian commercial contractors and help them grow.